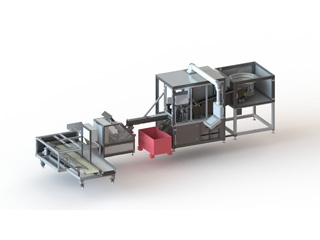

The increasing requirements regarding product quality and process reliability necessitate high precise testing machines. For these conditions, our testing and sorting machines are perfectly suited. It allows you to test any sort any kind of product in a consistent quality an in a continuous running process.

Testing Machine

Advantages

- High measurement accuracy (to 0,01mm)

- High output (up to 1300 pieces/min depending on geometry and testing)

- In-Line connection (optional with storage)

- Very high process reliability

- Gentle treatment of products

- Low setup times

- Customized design

Testing variants

- 2D and 3D geometry inspection

- Eddy-current testing

- Hardness testing

- Attack testing

Area of application

- Screws

- Rivets

- Stamped parts

- Sealings

- Small parts of every geometry

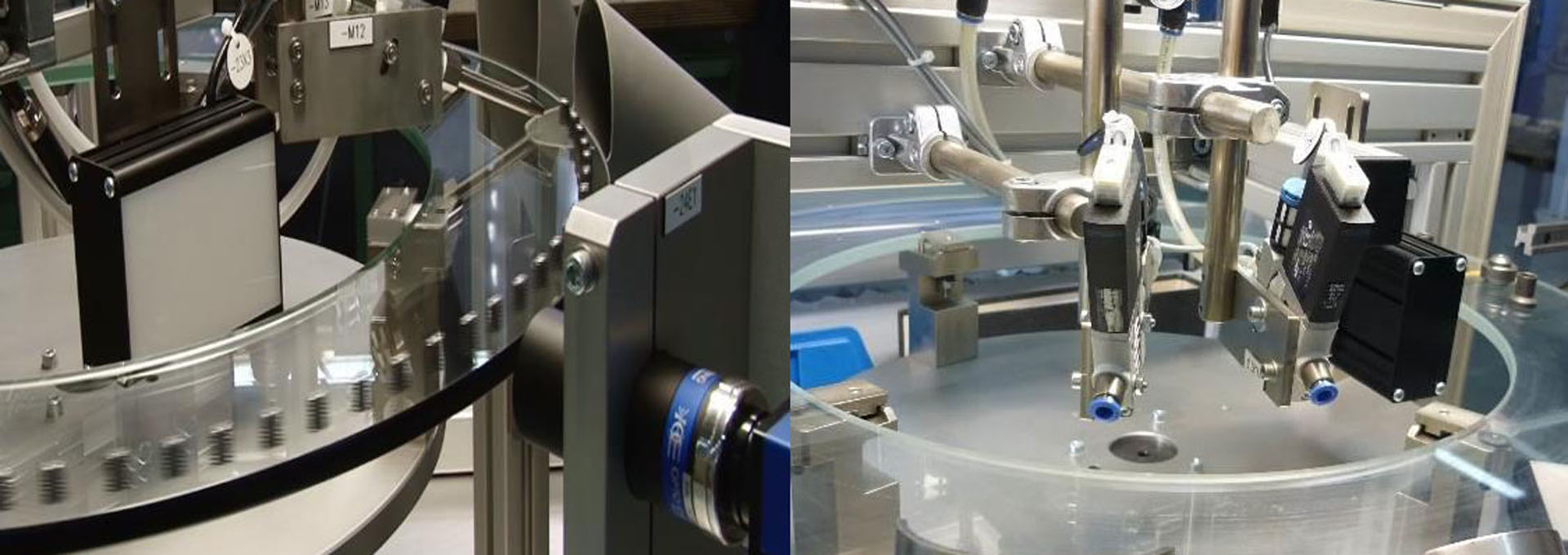

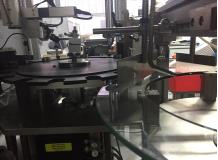

Inspection bench for safety valves

The precise setting of safety and high-pressure valves is always a challenge for the designers

and programmers of Grün & Köder. Because the wishes and requirements of our customers are often very versatile.

Valves from 10 to 100 bar can be set by a servo motor exactly on to the desired opening pressure.

Precision pressure sensors, control valves, pressure gauge and check valves ensure in conjunction

with the servo motor and the software the most accurate adjustment of the part.

By the use of changing parts, which are usually can be replaced without tools, different

valve sizes can be easily adjusted and checked.

The storage of various setting and testing programs, shortening the retool work enormously.

Further the parts can be exposed to a shock pressure of up to 200 bar.

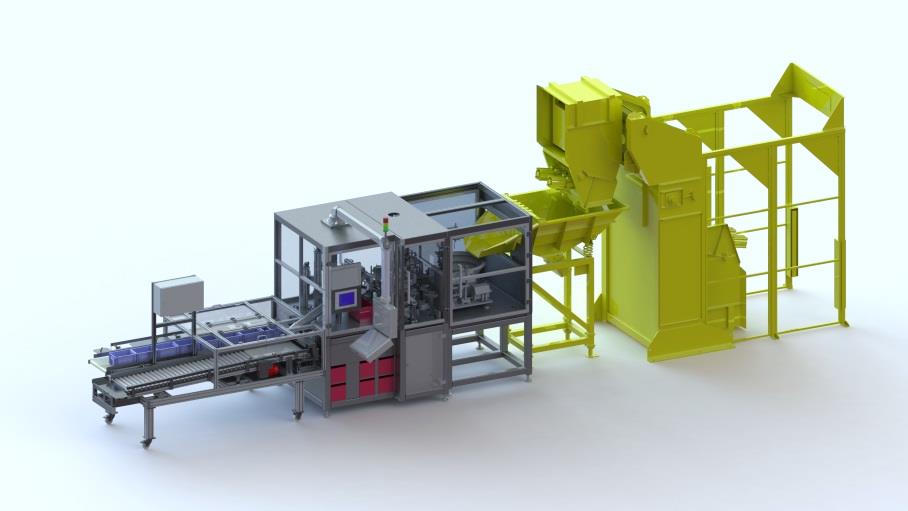

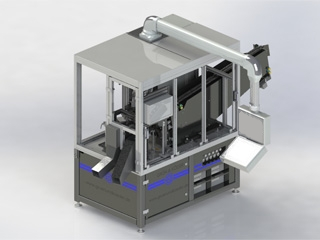

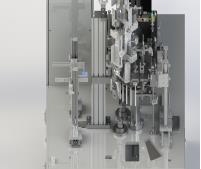

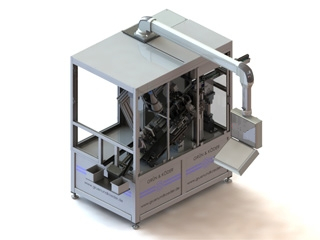

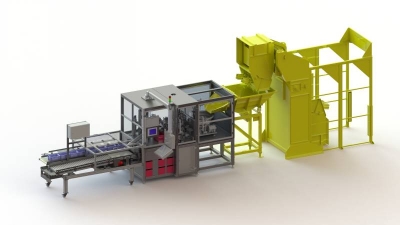

Sorting automation

for fasteners

The increasing requirements regarding product quality and process reliability necessitate high precise testing machines. For these conditions, our testing- and sortingmachines are perfectly suited. It allows you to test any sort any kind of product in a consistent quality an in a continuous running process. From feeding to testing to packing your products, we offer a perfectly synchronized and automated line concept.

STM 600

|

Diameter M0,7 - M36 |

|

Inspection stations with camera system |

|

3 D systems for surface inspection |

GTM 600

|

Diameter 2 -70 mm |

|

Camerasystem |

RPM 600

|

Diameter 3-16 mm |

LINE MODULES

|

Bag packaging module |

|

Feeder (yellow coloured) |