As chameleonic as our services

Our services are versatile - because our customers are too. Medium-sized companies as well as global groups from different industries have placed their trust in us for many years. Because as different as our customers are, they all appreciate the smooth cooperation with Grün & Köder. And, of course, tailor-made results: the complete systems designed and manufactured by us, which are delivered in the best quality to customer satisfaction.

Industry sectors

Automotive

An increasing number of vehicle types with ever shorter series runtimes is just as characteristic for the automotive industry as their demand for highly flexible manufacturing and assembly systems. A demand that we at Grün & Köder confidently fulfill

Electro Technology

In the sector of electro technology, our expertise is particularly in demand when it comes to individual assembly and inspection processes as well as complex functional tests for electronic assemblies.

Consumer sector

The product life cycles in the consumer sector are getting shorter and shorter while the variety in consumer goods is increasing. A starting point that requires flexible, reusable, modular solutions and assembly systems - the specialty of Grün & Köder.

Medical technology

Medical technology is an industry with very special requirements: user and patient safety must be the top priority at all times. A premise that we follow reliably throughout the entire product development process, starting with the first design draft.

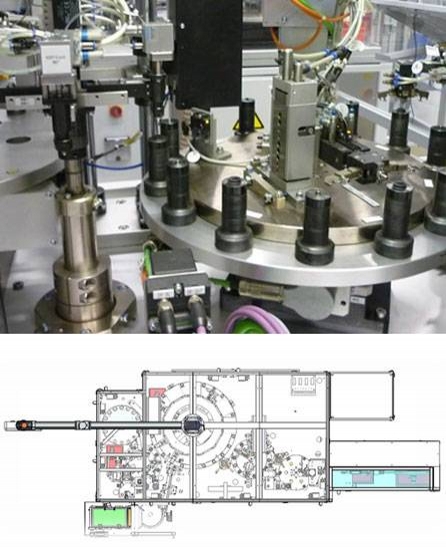

AUTOMOTIVE | EXAMPLE 1

Rotary-Indexing-Assembling-Machines: Sealing Ring Consisting of 5 Interlinked Rotary Indexing Tables

Compact rotary-indexing-assembly-machines, for assembling of sealing rings for diesel fuel injection pumps, consists of 5 interlinked freely programmable NC-rotary indexing tables with a total of 27 stations and 76 workpiece holders. The cycle time is 4 seconds / part.

- Feeding of plastic sleeves with camera inspection for dimensional accuracy (examination of the inner contour with endoscopic camera system and the lateral surface area with a circulating mirror in the incident light)

- Cleaning the plastic sleeves via blow out with ionized air

- Feeding of the spring in an etched shape (spring ring with supported sealing lips) as strip material (spring steel, thickness 0.1 mm) via drive operated coil handling with dancer control. The feed motion is cycled by means of a servo motor with an integrated camera inspection for the surface, type, form (bad parts are cycled through and not processed)

- Electro-pneumatic punching unit (servo punch with linear cylinder) for punching and forming of the spring via a bending tool with form punch in one work step

- The punched and formed spring is mounted 2 times in the sleeve, subsequent camera control assembly (complete, correct, incl. inspecting the bending)

- Subsequently a non-contact measuring of the component shape via air-gap-measurements (inner and outer diameters, 0,01 mm repetitive accuracy), as well as the height via tactile measurements

- The completed parts are discharged into a tube magazine buffer system

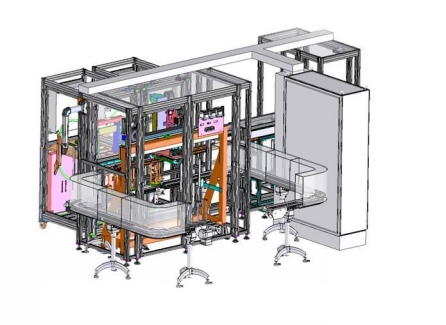

AUTOMOTIVE | EXAMPLE 2

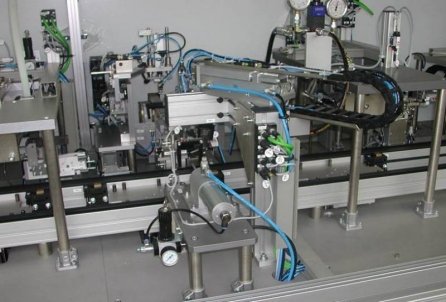

Linear-Transfer-Assembly-Machine: Exhaust-Gas-Recirculation-Valves (EGR-Valves)

Linear-transfer-assembly-machine as circulating workpiece carrier system for the assembly of EGR-valves with dual circulation, cycle time approximately 40 seconds.

- 2 manual workplaces for the insertion of complex components in the testing tables, respectively workpiece carrier circulation systems

- Separate rotary indexing tables for testing of tightness and leakage with marking

- Sorting the individual parts via a bowl feeder and linear vibratory feeder

- Separation and assembly of various components in the workpiece acceptance

- Riveting via collet chuck and riveting tool with hydraulic cylinder

- Mounting of bearings with integrated force-position-monitoring

- Greasing of the shaft with a dosing valve

- Caulking of washer via centring pin

- Laser-welding-station for welding via robot

- Workpiece acceptance system with read-write-head for identification at each station

- Separate discharging of bad parts

- Marking and labelling of the good parts

AUTOMOTIVE | EXAMPLE 3

Semi-automatic "Chaku-Chaku" Assembly Line for Automotive Thermostats

For production lots where complex automation is not economically viable, Grün & Köder can offer

workplaces based on the „Chaku-Chaku- principle. The operator transfers the components from station

to station, whereby he or she can operate up to 3 semi-automatic machines, as an example.

The various technological processes (e.g. riveting, caulking, spring assembly, etc.) are carried out

automatically and process reliability is monitored.

The "Chaku-Chaku" line shown here is designed for the complete semi-automatic assembly of automotive

thermostats with one operator.

Station 1:

- Manual loading of thermostat-elements

- Supported inserting of magnets, with force-position-monitoring caulking, with servo press

Station 2:

- Manual loading of thermostat-elements

- Conformance testing

- Supported inserting of springs and discs with automatic riveting (wobble riveting process)

Station 3:

- Manual loading of thermostat-elements

- Manual loading of casings

- Conformance testing via data matrix

- Automatic dismantling of the locking pin

- Supported placement of the O-rings

- Automatic greasing (volume dosing valve)

- Automatic assembly of thermostat casing with measuring of the protruding dimensions

- Storage of production data

AUTOMOTIVE | EXAMPLE 4

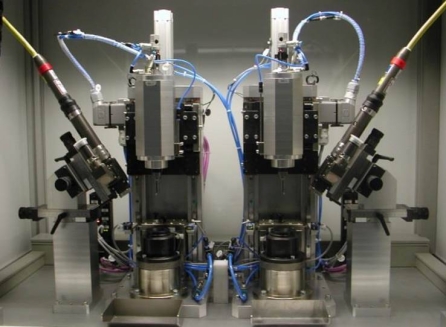

Laser-Welding-Machine, Dual

The laser welding machine is a semi-automatic / manual workplace, whereby an operator manually inserts and removes components.

In order to connect two parts technically, there are various methods.

Shown here is the laser welding of 2 parts (shells and bearing pins) of sheet steel in a dual

semi-automatic laser welding machine.

Centrical clamping of two components in a high precision rotary bearing pick-up with collet system.

The rotational movement is respectively servo driven technology, freely programmable in coordination with the laser beam.

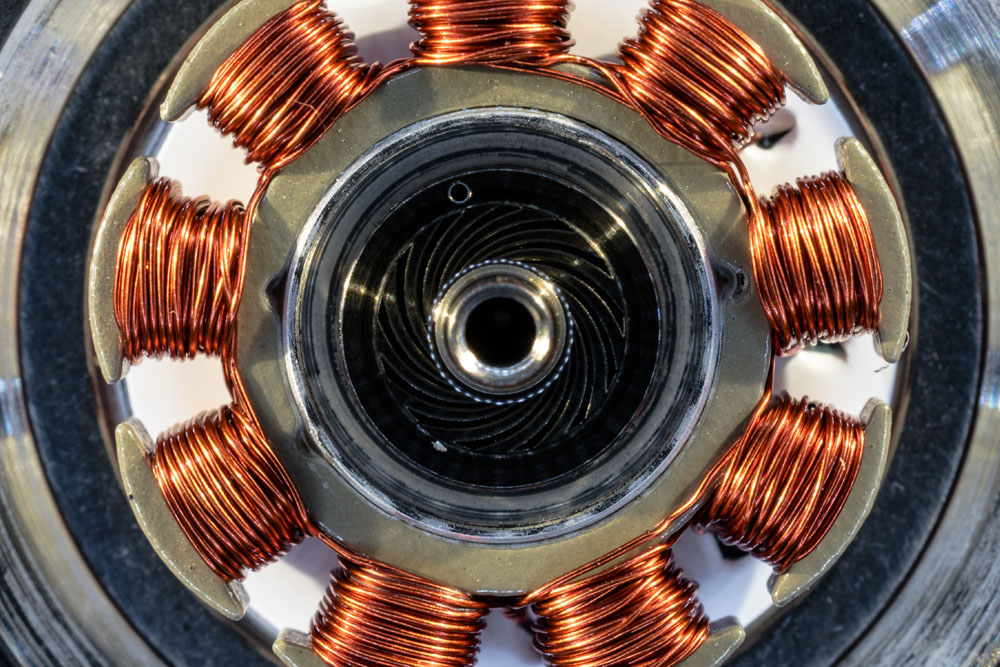

ELECTRO TECHNOLOGY | EXAMPLE 1

Assembly Machine - Final Assembly - Electric Motor on Workpiece Carrier System

Linear transfer machine with workpiece carrier system for final assembly of a drive motor for electrical power

steering with a performance output of 30 seconds per part, thereby 16 magnets were mounted with

force-position-monitoring in the first station.

The pressing processes are carried out via electrical screw presses with integrated force-position-monitoring.

- Magnets, shafts and tolerance rings are assembled in a lamella package

- Lamella package / rotor magnetization

- A-bearing mounted and pressed into A-cover

- Rotor mounted in A-cover and joined

- B-bearing mounted and pressed into B-cover

- Spring clips mounted on the stator

- Assembling of stator and B-cover

- Assembling of casing and joining

- Mounting and joining of magnetic sensor and belt pulley

- Mounting and joining of seal

CONSUMER | EXAMPLE 1

Rotary-Indexing-Assembly-Machines for Shaving Foam Caps

As product life cycles are getting shorter and the variety is steadily increasing, assembly machines

must be made more flexible so that several product versions with consistent quality can be reset with

minimum effort. For follow-up products the machine can be used with minor reconstructive measures.

The rotary indexing machine shown here assembles several versions of a shaving foam cap with a

capacity of 3,600 parts per hour.

- Sorting of parts via a bowl feeder and supplying with linear vibratory feeder, convertible for different diameters and shapes of the components

- Separation and transfer of parts in the workpiece holder of the rotary indexing table with direct inlet

- The workpiece holders are replaceable with quick-release-system without tooling

- Inspection of the correct assembly with a mechanical calliper

- Separate discharge of bad parts

- Counted transfer of good parts in cartons

- Automatic carton-exchange-conveyor-system

CONSUMER | EXAMPLE 2

Continuous-Motion-Machine for Sealing Cap Assembly

Especially in the growing market of mass production, disposable articles in the closure market, cam-controlled machines are needed. These high performance-assembly-machines, in continuous operational rotary carousal principle, are used for feeding and assembly of sealing caps with an output of 20 000 pieces / hour as shown here.

- Sorting of individual parts via a centrifugal feeder and feeding the parts with air supported

linear-vibratory-air feeder (airtrack)

- Continuous separation and transfer of parts using synchronous satellite tables

- Cutting a cross-shaped opening into the valves with the cutting tool

- Feeding of foil from carrier strip and with servo-controlled coil-unwinding-system

- Punching foil blanks and constant synchronized transfer onto sealing caps

- Camera inspection of the valve opening and correct position of the valve

- Separate discharge of bad parts

- Counted transfer of good parts in cartons

- Automatic carton-exchange-conveyor-system

CONSUMER | EXAMPLE 3

Rotary-Indexing-Assembly-Machines: Assembly of Window Fittings

Rotary indexing machines for assembly of 2 parts (bearing pin and retaining ring) in a window fitting with a capacity of 30 cycles / minute:

- Feeding of retaining rings and bearing pins with a bowl feeder and linear-vibratory-feeder

- Assembly of retaining rings and bearing pins with pneumatic handling unit

- Testing of correct assembly with optical sensor technology

- Separate discharge of the good and bad parts

MEDIZIN | EXAMPLE 1

Semi-automatic Machine for Welding and Marking of Foils

Machines that produce in sterile clean rooms are subjected to special requirements. For this

semi-automatic machine shown here, two foils and one inlay are inserted manually into the rotary

table nest. The foils are controlled via a camera. With temperature, pressure and time monitored

heating plates; the two outer foils are welded together.

After the welding the foil bags get an imprint with the laser marking device. Bad parts are not

labelled and automatically ejected. Good parts are removed by the operator from the intake.

Special features:

- Machine structure in stainless steel version

- Aluminium profiles without open longitudinal grooves

- Ergonomic workplace with two-hand start-up

- Manual loading control via camera, attached above the rotary table nest

- Rotary table nests in stainless steel

- Isolation of the laser marking device, including suction

- Setup without visible screws

- Electric control cabinet in stainless steel execution

MEDICAL | EXAMPLE 2

Packaging Machines - Bag Packaging from Strip Material

The medical packaging machines for bag packaging from strip material for the application in sterile

clean rooms for packaging of plasters, test strips or oral film strips.

Two foils are supplied from strip material and an inlay, which also comes from a strip, e.g. a

plaster, is guided onto a carrier foil, then punched and sealed.

The machine has the following sequences:

- Servo-driven roller feeds for the strip materials (packaging foils and carrier foils for packaging of inserts)

- Redirection of the carrier foil with knife edge, punching unit for punching of the insert and positioning of the insert on the bottom bag foil

- Feeding of the cover foil, this results in a foil sandwich which is then sealed on all four sides

- Sealing the packaging with temperature, pressure and time monitoring

- Subsequently more stations can be integrated if required by the customer, e.g. attaching a pull tab or a perforation

- In the final cutting station, the individual packages are cut

- Via a discharging flap, separate discharge of good and bad parts

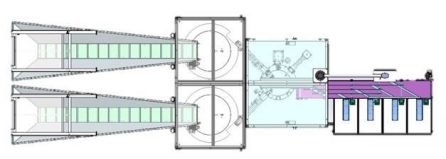

MEDICAL | EXAMPLE 3

Transfer machine for patches-forming

The medical duplex-forming machine for shaping patches for use in cleanrooms is consistently 2-lane

and consists of 2 duplex-forming stations.

Respectively 2 patches, which are fed as staple goods in a magazine, are separated with a handling with

blowing air which transfers the patches into the forming stations where they are formed (initially

heated and then water cooled).

- Feeding staple magazine via curve-belt-system

- Automatic magazine change with monitored stoppers in removal position

- Removal-handling-system with vacuum gripper in double execution with linear axis

- Transfer of 2 pre-cut parts into 2 form moulds, where parts are fixed by vacuum and moved by a drawer

- Preheating by 2 infrared heaters with hold-down device and forming via vacuum and 2 water cooled form punches

- Cooling conveyor belt with ventilators, transfer the formed parts to the automatic staple unit into magazines