From manual workplaces to high-performance machines

We translate customer requirements

into efficient technologies

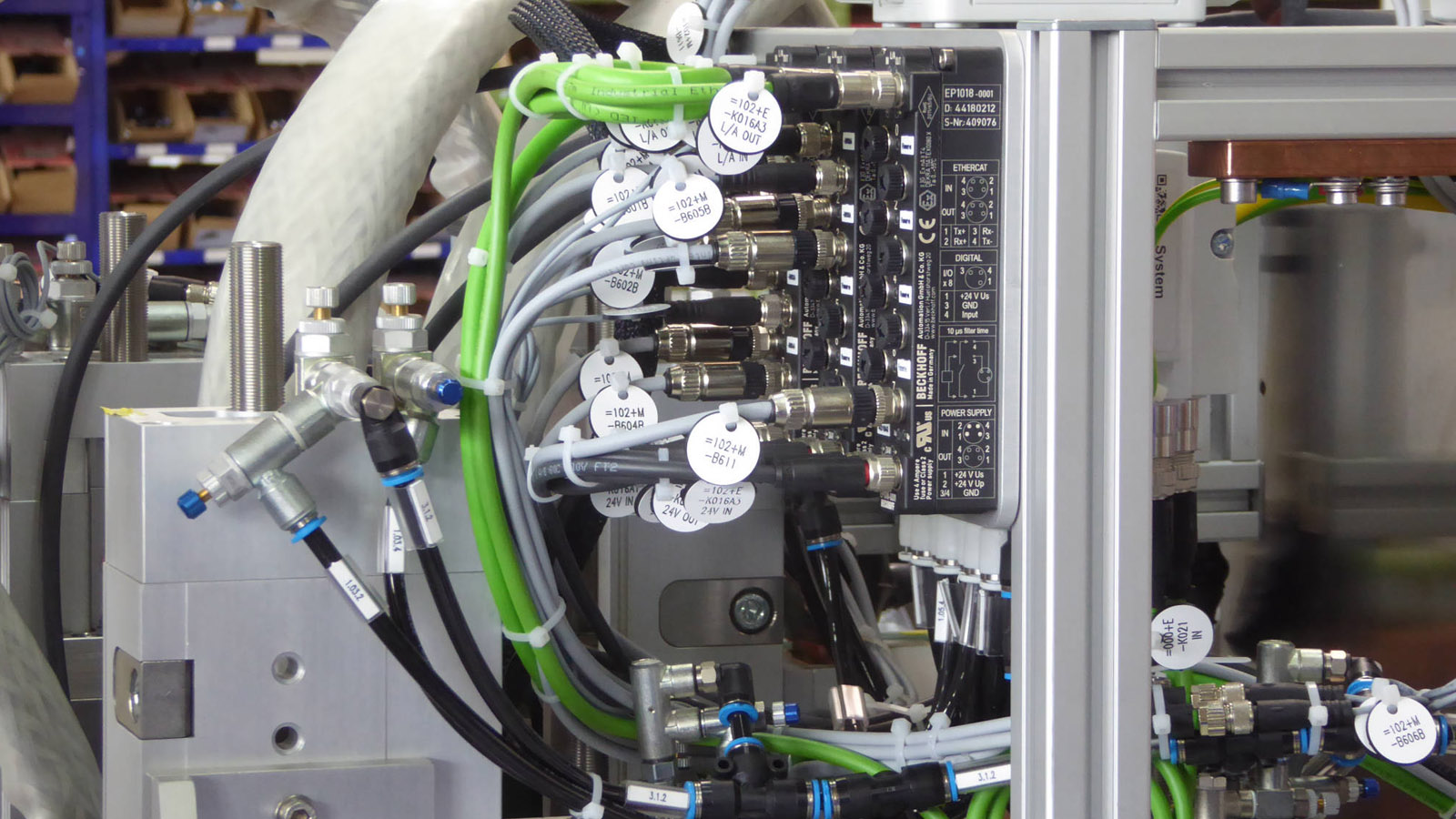

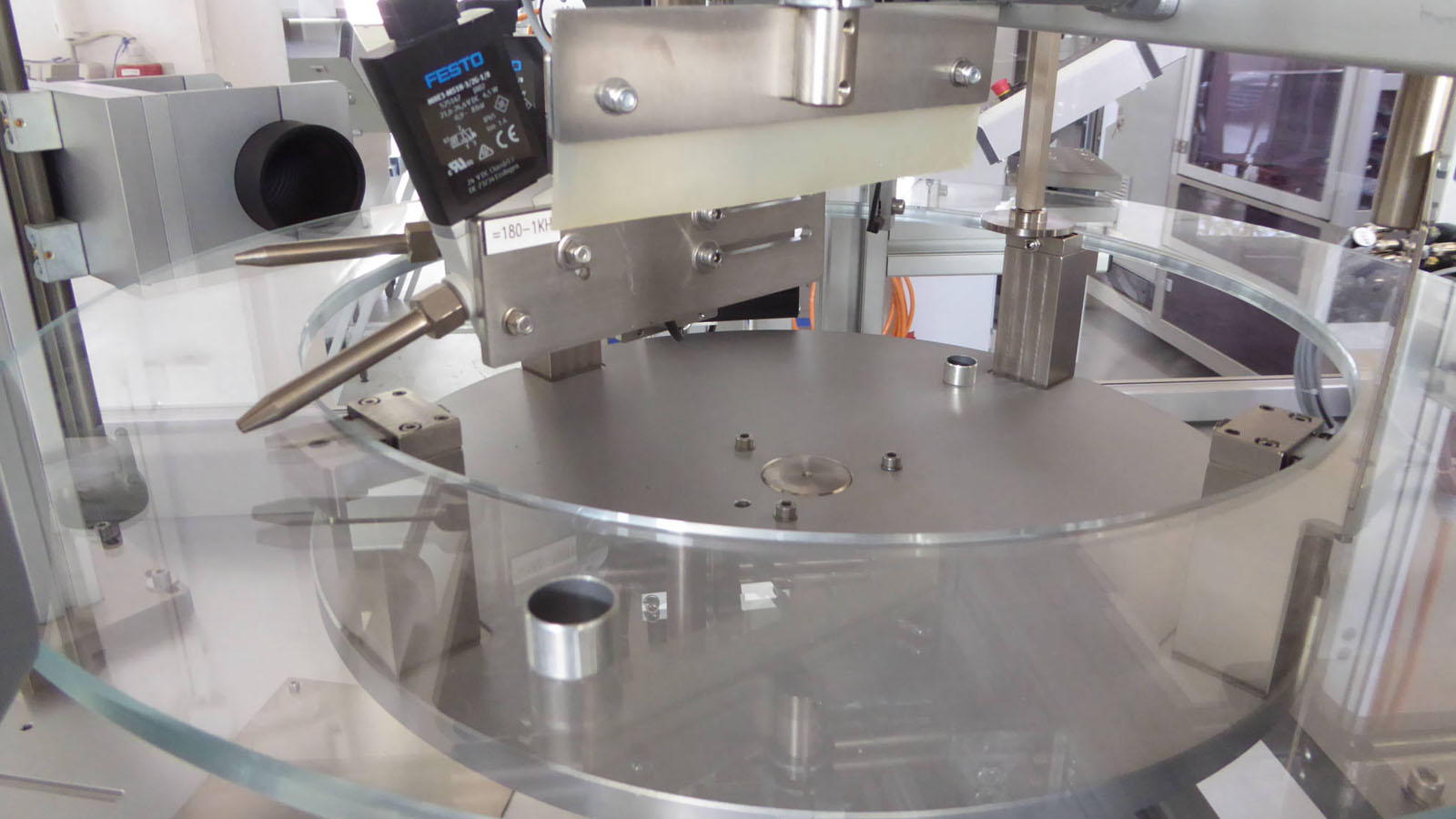

From manual workplaces for complex parts to complete automatically high-performance machines with yearly performance of several million parts – Grün & Köder translates specific customer requirements into efficient technologies. With great flexibility and expertise, we plan, develop and build machines and systems for processing, assembly and inspection of functional parts. For various industries and applications.

- HANDLING TECHNOLOGY

- PRODUCTION PLANTS

- ASSEMBLY LINES

- INSPECTION MACHINES

- SPECIAL MACHINES

-

For a small lot size, but with a high process reliability of the assembly processes or non automatic manageable components (due to the component size or shape), the manual workplace or semi-automatic solution is ideal. | more

-

From simply structured to fully automatic: We design a wide range of long-life production machines with exactly the level of automation that meets your requirements. | more

-

With our assembly lines the perfect concatenation of different production processes is achieved - adapted to specific customer requirements. Upon request, camera-based production monitoring ensures continuous quality control. | more

-

The increasing requirements regarding product quality and process reliability necessitate high precise testing machines. For these conditions, the PACE is perfectly suited. It allows you to test any sort any kind of product in a consistent quality an in a continuous running process. | more

-

Decades of experience, well-founded technical competence and distinctive innovative power: We at Grün & Köder are the ideal partner when it’s about special challenges. Idea, engineering, conception, production - we deliver tailor-made, comprehensive solutions. So comprehensive that we can, if desired, also train your employees so that you get the maximum benefit from your new production machine.

Our range of services also includes the fully automatic assembly and completion of your products, including quality controls and final packaging. | more

News

What’s new at Grün & Köder? Here you can find out.

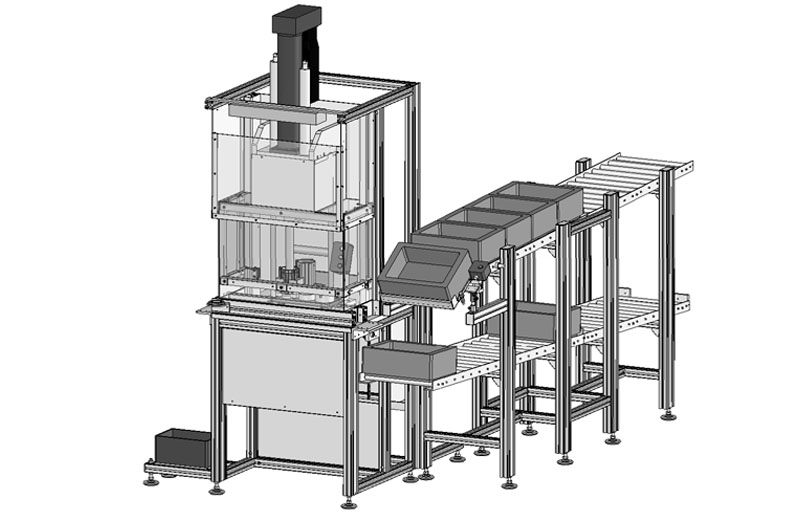

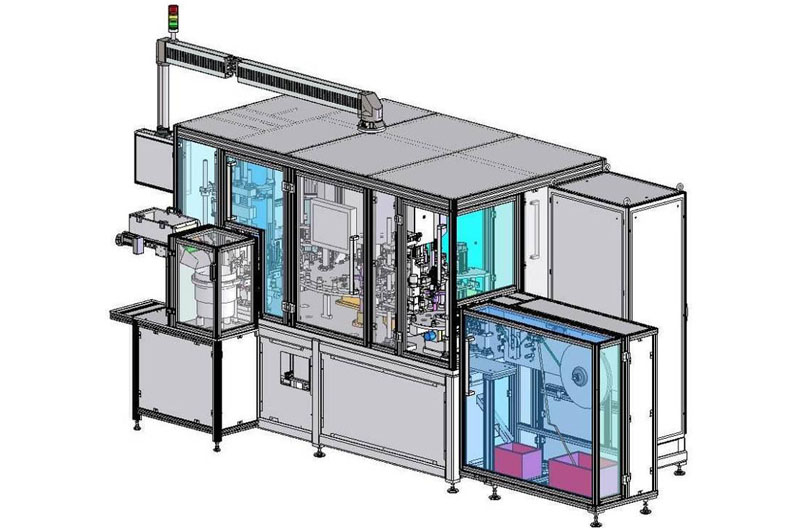

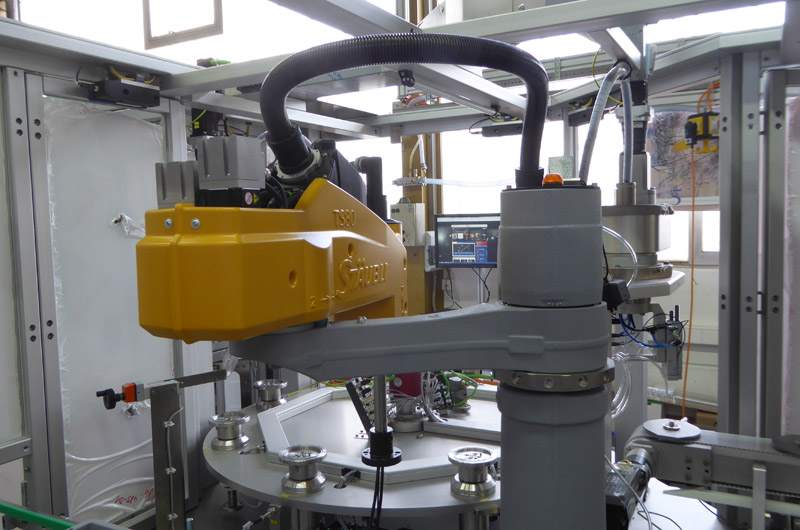

Labeling, filling and sealing in one by combining MFE and FSK

Fully automatic labeling, filling and sealing in one go is made possible by combining our labeler MFE

with the FSK filling and sealing system.

The labeled containers are transferred directly from MFE to FSK via a transfer handling system for further processing.

After filling, the containers are sealed airtight. This is followed by an inline leak test for a 100% check.

The finished containers are then transferred to a discharge conveyor.