In a manufacturing process, there are often multiple, consistent tasks that require different operations. For example, if different parts from different containers are needed for assembly them. Here, the decisive factor is the choice of the right robot application. In this case, the robot must have several grippers in order to be able to feed the different parts precisely to the assembly process after removal. Following assembly, for example in the packaging process the products must be stack in various boxes with different endpoints.

Especially for tasks with high quantities in 3-shift operation, where recurring precision, fast cycle times and positioning accuracy are required, robotic applications are most suitable.

Our customers benefit from a decided advantage: With Grün & Köder you have a high-performance project partner at your side, who is very experienced, knows the market environment well and with its expertise from the conception to the promising project realization, all work steps are united under one roof. From the selection of the right offer, to the integration of the robot application in the production plant to the professional robot programming by our system specialists. So we can guarantee the desired result in both functional and qualitative terms.

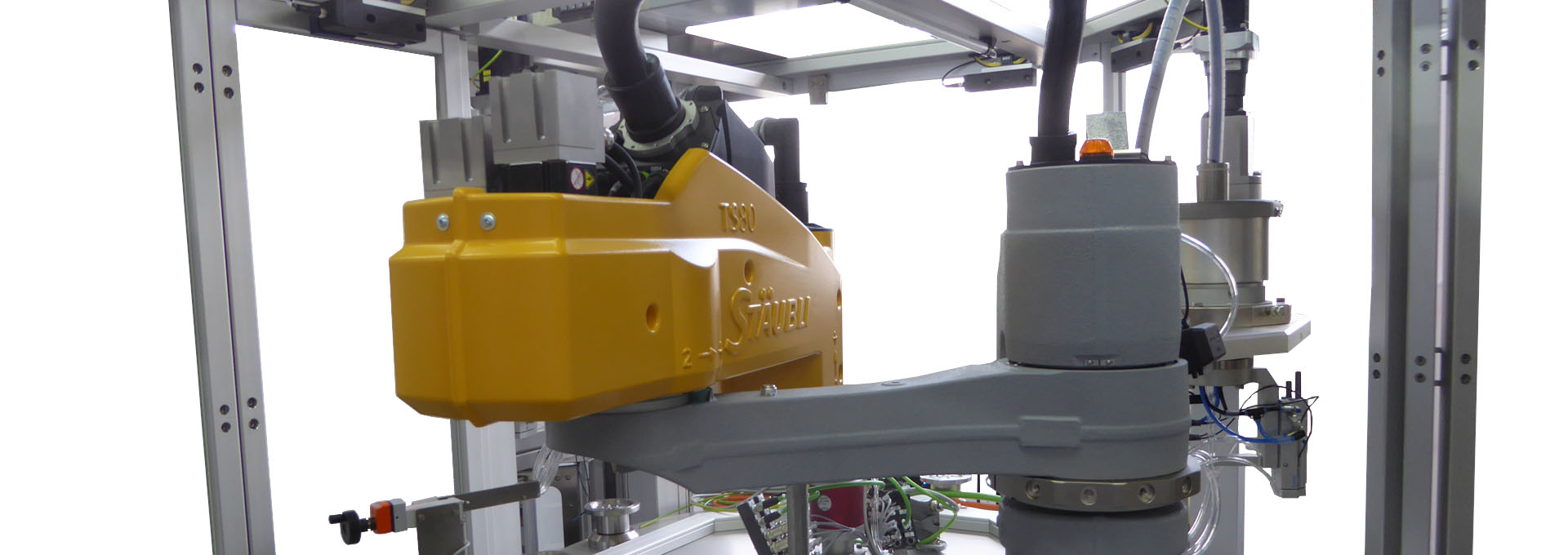

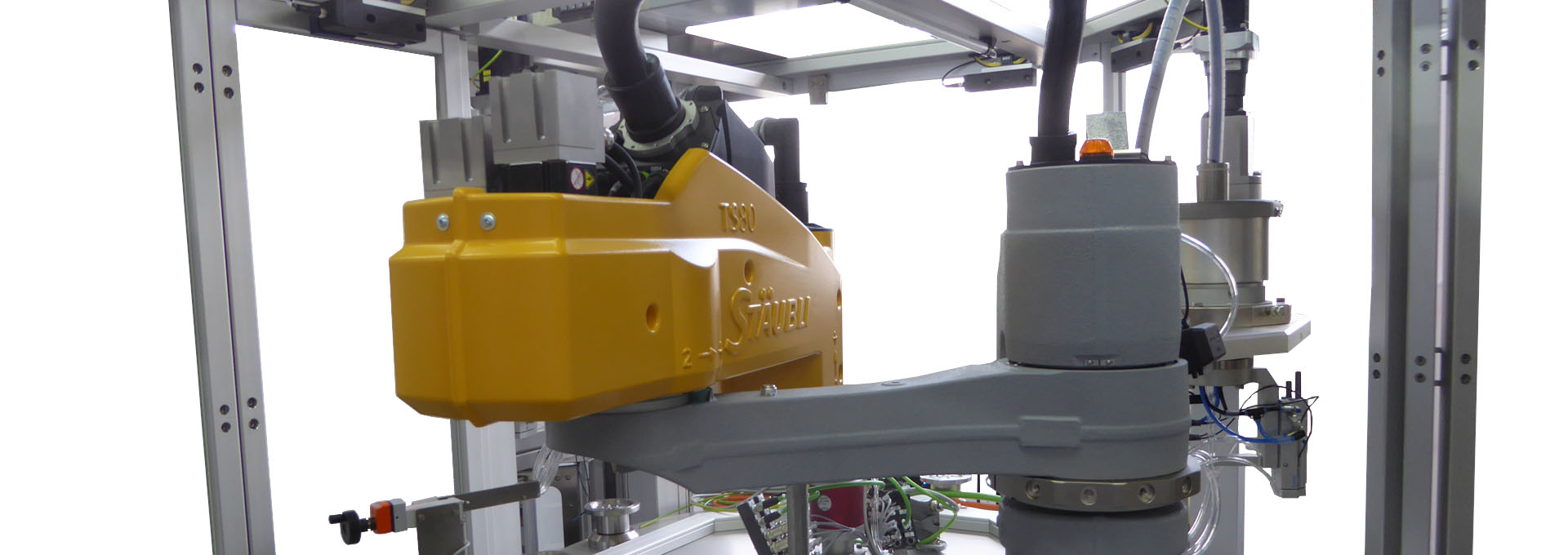

Roboterzelle setzt neue Maßstäbe

Grün & Köder und Faude Group bieten gemeinsam eine Roboterzelle an, die in kontinuierlichem Transport, Produkte erkennt, klassifiziert und in die entsprechende Behältnisse einsetzt.

Industriebereich

- Teile zuführen

- Lage erkennen

- in Behälter einsetzen

- Verpackungen stapeln

- Kommisionierung

- Karton beladen

Lebensmittelbranche

- Backwaren zuführen

- Fleisch und Fisch

- Obst und Gemüse

- Lage erkennen

- Gewicht erkennen

- Mixpackungen

- Sortieren

- Dekorieren

- Klassifizieren

- und und und……