Depending on the process configuration, the quality of the parts or products to be manufactured and the required cycle times, we offer our customers individually tailored rotary indexing or linear transfer machines.

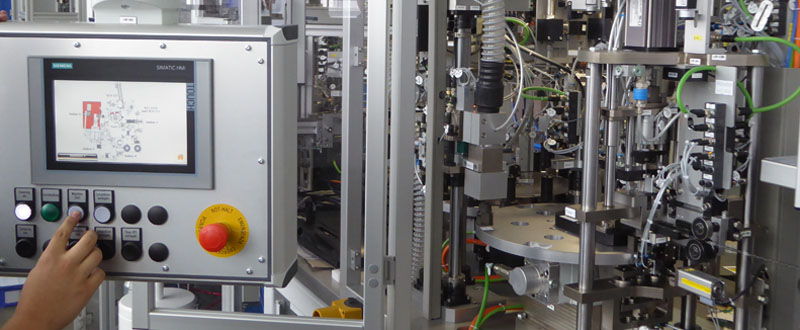

Rotary Indexing Machines

As product life cycles are getting shorter and the variety is steadily increasing, assembly machines must be made more flexible so that several product versions with consistent quality can be reset with minimum effort. For follow-up products the machine can be used with minor reconstructive measures.

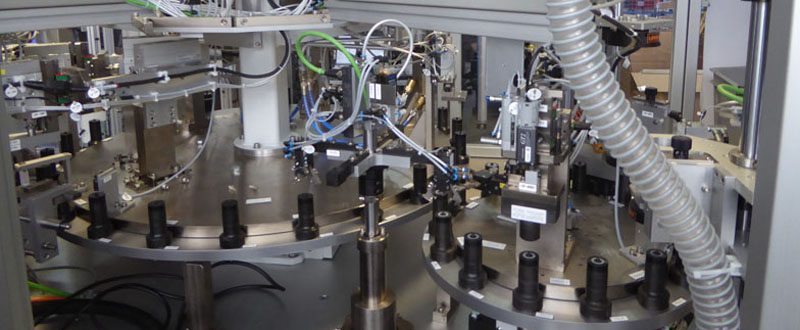

Rotary indexing machines with up to 24 stations per rotary indexing table and the respective stations are equipped with multiple tracks (up to 12 tracks). They achieve cycle performances of up to 60 cycles per minute. It is possible to combine several rotary indexing tables with a direct handover, e.g. for pre-assembling and testing of components in satellite tables.

The rotary indexing machine shown here assembles several variants of a shaving foam caps with a capacity of 3,600 parts per hour.

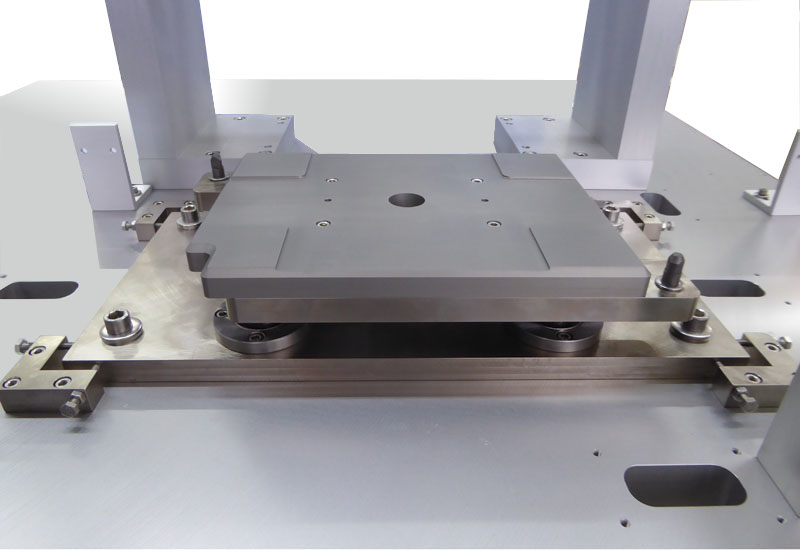

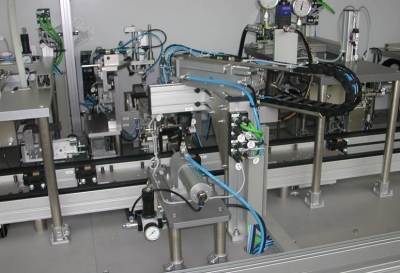

Linear Transfer Machines

With flexible assembling applications where automated and manual work steps must be combined, workpiece carrier systems are used. The carrier system transports the components from one station to the next fully automatically. The work steps are either processed, as required, fully automatically in the modules or in manual workplaces.

In these systems, the degree of automation can be gradually increased by integrating more automated modules. As a result, these systems are extremely flexible, expandable and resettable, e.g. for new product versions, similar series, higher quantities or new assembly processes, respectively testing processes. Of course, these systems can also be converted for follow-up productions or integrated into further production lines.

Another area of the linear transfer machines are applications, where components are accessible from both sides, because manufacturing processes, e.g. on both ends of a pipe / hose have to be applied. These processes can only be preformed with great difficulty or not at all on a rotary indexing table. Furthermore linear transfer machines are applied when a customer specifies, e.g. a freely accessible side of the machine and the complete feeding action of single parts at the rear side of the machine or a simple lack of space.