Project examples

References

INSPECTION MACHINES

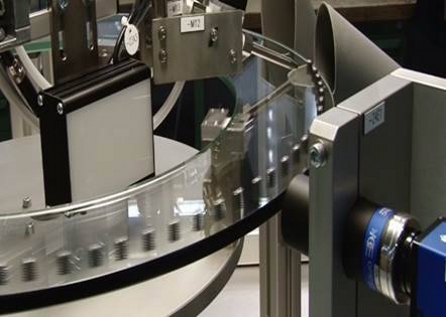

Glass-Table-Testing-Machines for all-round Inspection

The continuously rotating glass table ensures all-round examination of the components at a performance of up to 600 parts / minute.

What can be tested and qualified:

gaskets, O-rings, formed parts, hexagonal nuts, square nuts, special nuts, punch die parts, plastic

moulded parts, electrical contact parts, contacts, magnets (non-magnetic)

Industrial sectors:

automobile supplier, electrical industry, fittings industry, plastic industry, punching technology,

pharmaceutical industry, cosmetic and food industry

References

References

What distinguishes PQM 600:

- compact machine frame in aluminium profile design

- servo-driven rotary-glass-table

- precise carriages and stands for adjusting the cameras, incl. threaded spindles

- high resolution cameras

- SPS-control from Siemens with control panel

- Machine guarding made of aluminium profiles and polycarbonate screens

DDue to the stringent customers requirements the interplay between mechanics, electronics and image processing plays a central role.

References

References

INSPECTION MACHINES

Inspection machine safety valves

The testing facility for safety valves is a manual workplace with manual insertion and removal of the components by an operator.

The opening pressure of valves, from 10 to 100 bar, can be accurately adjusted via a servo motor.

Precise pressure sensors, control valves, pressure gauges and non-return valves ensures, in conjunction

with servo motors and the software, accurate calibration of test items.

Through the use of exchangeable parts, which can be exchanged without tools, the different valve sizes

can be adjusted and tested without a problem.

Also the backup of different setting and testing programmes shortens the reconstructive task enormously.

Likewise the adjusted test items can be exposed to a shock pressure of 200 bar.

References